Using Skore in Lean Process Improvement

Process Improvement is a vital part of Lean activities and more and more Lean teams are looking for different ways to improve the way they achieve their company objectives. In this blog we’ll show you how Skore is a great platform to enable your team to gain success in Process Improvement.

Make your Process Discovery Lean – How Skore is different.

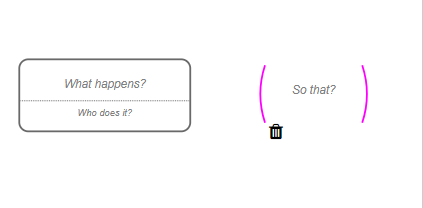

In our efforts to improve the effectiveness of process discovery workshops we looked at how processes are described. A number of notations and approaches are available but we wanted something simple. Not to remember a lot of symbols or explain them to others and certainly we didn’t want to waste time discussing their meaning. So we reduced the shapes we use to 2.

We did want people to think about the value of their work so we introduced the Why box. This ensures that for every piece of work that we describe in Skore we need to have a discussion about why we do it. That discussion could be 15 seconds, or it may take 15 minutes, but it’s essential to know whether the work is adding value or not. This is Universal Process Notation and you can read more about it here.

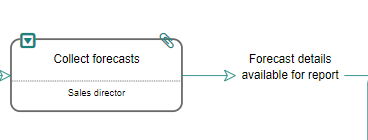

We created a software interface easy enough to use in a live environment and capture a process at the speed of conversation. This is done on a screen in front of people while they describe the process. We recognised writing sticky notes distracts from the flow of information from participants. Whether re-writing a spelling mistake or having to completely rearrange all the notes on the board because they missed an important step out somewhere. UPN also enables everyone in your organisation to read and understand the processes they are following – a key requirement for any successful project.

Learn more about Lean Process Improvement by becoming a member of our resource community and getting your hands on exclusive content such as guides, cheat sheets and blogs.

Of course the by product of this ‘process improvement’ is everything you capture is immediately stored digitally. There’s no need to take photos, roll up the paper and transcribe it into various formats afterward. Content is shared instantly at the end of the workshop. In a recent example one of our partners saves 2 days of follow up work for each workshop they run. At around 100 workshops per year – that’s a significant saving of 200 days.

Using Skore for Lean Process Improvement

Finally Skore addresses the waste issues concerning the ongoing management of documents following a workshop. Huge amounts of information are gathered, not just process flows. Roles and responsibilities, risks, timings, costs, delays, questions, actions, issues, the list goes on. All are documented somewhere and relate to specific parts, or steps, in the process. They must be updated and kept in sync. Skore stores this directly against the process so that any change you make will instantly highlight any dependencies and be reflected through all the information.

Using Skore enables Lean teams to ensure that their information gathering and process mapping is efficient and effective. Lean consultants themselves should be able to recognise that sometimes we all need to change and embrace the new ways, even if that means recognising that Lean approaches can produce wastage too.

Skore is a process improvement software platform. it reduces the capturing processes stage from weeks to days. Find out more about Skore here